What is T Nut?

The widespread use of aluminum profiles in various industries has created a suitable platform for the production of various accessories to improve their performance. One of these accessories is the T-nut. The T-nut is one of the main components in the connections of aluminum extrusion and has a wide range of applications in the construction of aluminum structures. Connecting profiles and any other parts to these profiles is not possible or seems difficult without T-nuts. Now all of this explanation makes us eager to know how these functional T-nuts work. T-nuts are often made of zinc-plated steel and have very high strength.

Different types of t-nuts?

There are various types of t-nuts but their applications are the same, to connect accessories, profiles, and connectors. The only difference is in how they are used and put in aluminum profiles due to their geometric shape and rounded edges. Two of the most important types of T-nuts are hammerhead T-nut and sliding T-nut. The main difference between hammerhead and sliding t-nut is, that you can insert hammerhead t-nut into the slot at any point you want. However, with flat T-nuts (sliding t-nut), you can only insert the nut through the profile two ends.

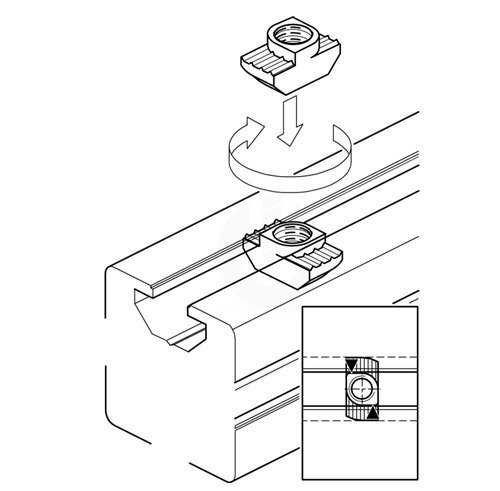

What is Hammerhead T-nut and How Does it Work?

Hammerhead T-nut is a model that has rounded edges and it can make it easy to use, means that by placing the T-nut inside the slide of the aluminum profile at any point and turning the screw inside the nut to fasten it, the nut starts to turn and then is pulled upward and engaging with the inner edge of the profile. By tightening the screw further, the nut becomes more secure in its place. However, it should be noted that over-tightening the screw can deform the edge of the profile.

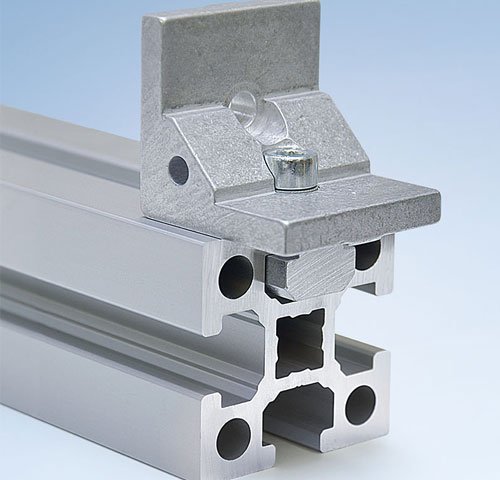

What is Sliding T-Nut and how does it work?

Sliding T-nut is a model that has a rectangular shape. It is produced in different slide and screw sizes and is made of steel. As you can see in the following picture, to use this nut, you can easily insert the nut via the end of the profile and move it to the place that you need. It can make it easier to use because they cannot move a lot within the slide. However, you need to insert those nuts into the slide and then start to connect profiles and brackets, and future works are a little hard because for example if you decide to install a new handle in the middle of a profile with closed ends (due to other profiles and connectors) you first need to open those brackets to insert new nuts then install that handle.

Anyway, Sliding T-Nut is the most popular type of T-nut because it is easy to use and affordable.

T-nut applications

The main application of T-nuts is to connect profiles and attach various accessories to them. To connect aluminum profiles at a 90-degree angle, aluminum corner brackets should be used. Additionally, double T-nuts can be used to connect profiles in line (in the same direction), although this type of connection is not technically sound good, it can be used when necessary. As mentioned, to attach various components to aluminum profiles such as stepper motor supports, T-nuts, and screws should be used. See an example of the T-nut application in the image below.

how do select the correct type and size of T-nuts?

Based on the application and situation, you need to decide which type of T-nuts are more appropriate. After you know the type, you need to select the size that matches your profile. It means that you need to choose the nut size based on the profile slot size. There are different profile slot sizes in the market and the nut size should be compatible with the slot size. the following list shows 3 of the most important series that exist in the market:

Slot 6: For 20 series profiles like 2020 or 2525. For this profile size, the slot size is 6mm.

Slot 8: For 30 series profiles like 3030 or 3535. For this profile size, the slot size is 8mm.

Slot 10: For 40 series profiles like 4040, 4080, or 4545. For this profile size, the slot size is 10mm.

Notice: In the 40 and 45 profile series, most of the time you can use the same nut size but it is recommended that for the 45 series profle, use the 45 series nut.