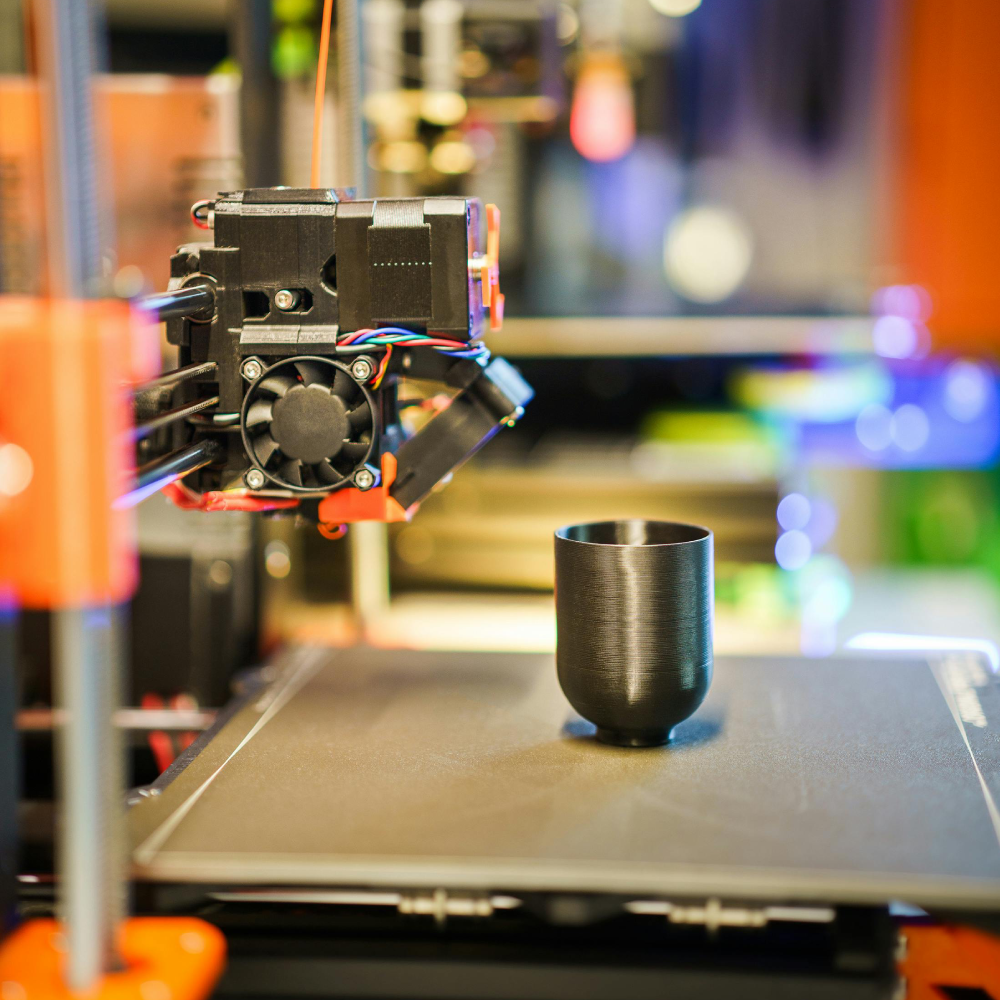

Build Your Own 3D Printer: The Ultimate DIY Parts Guide for Makers & Hobbyists

If you’re a DIY enthusiast or maker looking to build your own 3D printer, and you need to find the right 3D printer parts list, you’re in the right place. Whether you’re planning a CoreXY, Cartesian, or custom design using aluminium extrusion profiles, this guide will walk you through every essential component you need to bring your printer to life.

1. Frame and Structure

Aluminium Extrusion Profiles

These modular T-slot profiles (such as 2020, 2040, or 3030) serve as the foundation of your printer. They’re lightweight, strong, and easy to assemble using standard connectors and fasteners. Aluminium extrusion profile makes it easy to expand or modify your printer frame in the future.

Corner Brackets and Connectors

Used to join extrusions at fixed angles, brackets and connectors are crucial for creating a rigid frame. L-brackets are easy to install, gusseted brackets add extra strength, and hidden connectors offer a cleaner appearance for professional-looking builds.

T-Nuts and Fasteners

What is a T-Nut? These specialized Nuts slide or drop into the extrusion’s T-slot, allowing you to attach components anywhere along the profile securely. Combine them with M5 screws, bolts, and washers to fasten everything from motors to panels.

Rubber Feet or Pads

Placing rubber feet on the bottom of your frame reduces vibration and noise. They’re a small investment that significantly improves stability and overall print quality, especially on hard surfaces.

2. Motion System

Stepper Motors

NEMA 17 stepper motors power the motion of your printer’s X, Y, and Z axes, as well as the extruder. They’re known for their precision and reliability. You’ll typically need four or five motors, depending on your printer design.

How to Choose the Right Stepper Motor for a 3D Printer

Linear Rails or Rods

These components guide your moving parts along their axis. MGN12 linear rails are a premium choice for smooth, accurate movement. Alternatively, smooth rods paired with LM8UU bearings are more affordable and still widely used.

Linear Rails vs. Rods in 3D Printing – Which Should You Choose?

Belts and Pulleys

GT2 timing belts are standard for X and Y axis motion due to their flexibility and accuracy. Combine them with 20-tooth pulleys and idlers to ensure synchronized movement and tension control.

Belts and Pulleys in 3D Printing

Leadscrew or Ballscrew

Used mostly for the Z-axis, leadscrews provide high torque and precise vertical motion. T8 leadscrews with brass nuts are common, while ballscrews offer improved efficiency for high-end builds.

Lead screw vs Ball screw: 7 must-know differences

3. Hotend and Extruder

Hotend Assembly

The hotend melts your filament for extrusion. All-metal hotends handle higher temperatures, while PTFE-lined options are more budget-friendly. Key parts include a heater cartridge, thermistor, and often a silicone sock to help maintain consistent heat.

Nozzles

The nozzle size controls print resolution and speed. Most printers use a 0.4mm nozzle, but it’s wise to keep a variety (0.2–1.0mm) on hand for different projects and materials.

Extruder

The extruder pushes filament into the hotend. You can opt for a direct drive system (great for flexible filaments) or a Bowden setup (lighter moving parts). Key components include a drive gear, motor, and tensioning mechanism.

Cooling Fans

Cooling is critical for quality prints. A part cooling fan (usually 4010 or 5015 blower) solidifies filament quickly, while a hotend cooling fan (3010/4010 axial) prevents heat creep that can cause clogs.

5 things you must know about 3d printer extruder and hotend

4. Print Bed

Heated Bed

A heated bed improves print adhesion and minimizes warping. Aluminum beds heat evenly and are available in 12V or 24V versions, typically in MK2 or MK3 formats.

Build Surface

Your print surface impacts adhesion and part removal. Options include PEI-coated spring steel, borosilicate glass, and textured magnetic flex plates. Each has pros and cons depending on filament type.

Leveling System

Manually leveling the bed involves springs and thumb screws at each corner. For more consistent results, auto bed leveling systems like BLTouch or inductive sensors map the surface before each print.

5. Electronics

Mainboard / Controller

The mainboard is your printer’s brain. Popular choices include BTT SKR, Duet, and MKS boards. Look for compatibility with your firmware of choice (Marlin, Klipper, etc.) and support for features like silent drivers or Wi-Fi.

Stepper Drivers

These control motor current and precision. TMC2209 drivers are quiet and efficient, while older A4988 or DRV8825 options are less refined but still functional.

Power Supply

The PSU powers your entire printer. Choose a 12V or 24V unit with enough wattage to support the heated bed, hotend, and electronics. Most builds require at least 240W.

Thermistors

Thermistors monitor the temperature of the hotend and heated bed. Most setups use 100k NTC types, which are accurate and widely supported.

Endstops

Endstops tell the printer when each axis has reached its limit. Basic mechanical switches work well, but optical and Hall-effect sensors offer better precision and durability.

Screen

Your display lets you control the printer without a computer. LCDs with rotary knobs are standard, but many builders prefer touchscreen interfaces for ease of use.

6. Sensors and Safety

Auto Bed Leveling Sensor

BLTouch and similar sensors probe the bed to create a mesh map for compensation, ensuring consistent first layers even on slightly uneven surfaces.

Filament Runout Sensor

These sensors detect when filament runs out and pause the print, preventing failed prints on long jobs.

Safety Hardware

Thermal fuses and external MOSFETs protect your board and wiring from overheating. Solid-state relays can add further reliability, especially for high-current components.

7. Wiring and Assembly Essentials

Wiring and Cables

Use heat-resistant silicone wiring in appropriate gauges (14–22 AWG). Pre-crimped connectors save time and reduce build errors.

Cable Management

Keep wiring tidy with drag chains, braided sleeving, and zip ties. Neat wiring improves airflow, reduces snags, and looks more professional.

Connectors

Reliable connectors like XT60 (for power), JST (for sensors), and Dupont (for signal lines) help ensure stable operation and easy servicing.

Assembly Aids

Useful tools and supplies include heat shrink tubing for insulation, ferrules for cleaner wiring, and a crimping tool for creating strong, secure connections.

8. Firmware and Software

Firmware

Firmware runs your printer’s hardware. Marlin is beginner-friendly and widely supported. Klipper offers advanced motion planning, while RepRapFirmware excels in web-based control.

Slicer Software

Slicers translate your 3D models into printable instructions. Cura, PrusaSlicer, and SuperSlicer all offer customizable profiles for different printer setups and materials.

Interfaces

Upload print files via microSD, USB, or Wi-Fi. Remote monitoring and control tools (like OctoPrint or Fluidd) can further streamline your workflow.

Conclusion

Building your own 3D printer is a rewarding challenge that gives you total control over performance, size, and upgrade path. By choosing quality parts and understanding how they work together, you’ll build a reliable machine capable of producing professional results. You can find all the 3D printer components on the Zivon shop.

DIY 3D printing is such an exciting area, but it can be difficult to navigate all the options out there. I found the list of parts really useful. What’s the best way to balance performance and cost when building a machine from scratch?