If you’re working with aluminium extrusion profiles, you’ve probably come across T-nuts — small but essential components that hold everything together. Whether you’re building a custom 3D printer frame, a workbench, or an automation rig, T-nuts are what make the modular nature of aluminium profiles possible.

In this guide, we’ll explain what T-nuts are, how they work, and how to choose the right type for your project.

What Is a T-Nut?

A T-nut (sometimes called a sliding nut or profile nut) is a fastener designed to fit inside the T-slot grooves of aluminium extrusion profiles. It provides a threaded hole for bolts or screws to anchor brackets, plates, or other components to the profile. Once inserted into the groove, the T-nut stays securely in place — allowing for easy assembly and disassembly without drilling or welding.

How Does a T-Nut Work?

The process is simple:

Insert the T-nut into the T-slot of the extrusion profile

Align it with the mounting point

Tighten a bolt or screw into the nut to secure your part

Depending on the type of T-nut, it either slides into place from the end of the profile or drops in from the top. Once tightened, the nut bites into the groove and stays firmly locked in position.

Types of T-Nuts (And When to Use Them)

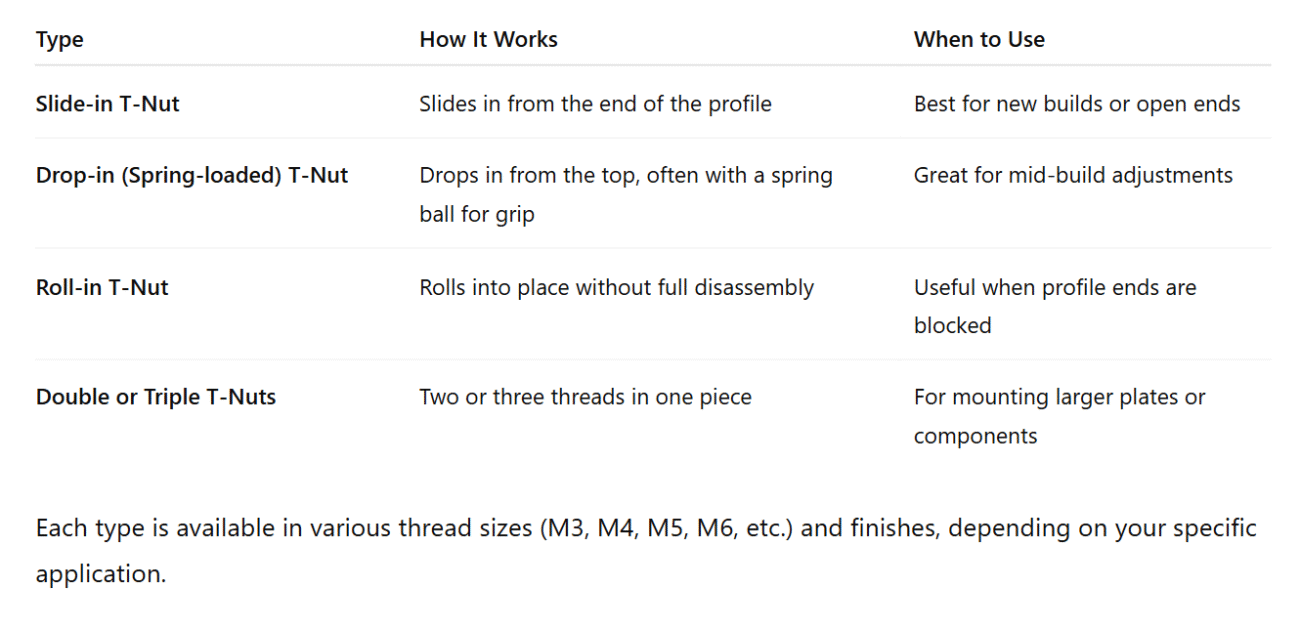

There are several common types of T-nuts used with aluminium extrusion profiles, each suited to different situations.

Slide-in T-nuts are inserted from the end of the profile and are ideal for new builds or when the ends are open.

Drop-in T-nuts, often spring-loaded with a ball bearing, can be added from the top and are perfect for mid-build adjustments.

Roll-in T-nuts rotate into the profile’s slot and are especially useful when the ends of the extrusion are blocked or already assembled. For heavier-duty needs.

Double and triple T-nuts provide two or three threaded holes in one piece, making them great for mounting larger components or plates.

Most types come in standard thread sizes like M3, M4, M5, and M6, with different finishes available based on your project’s needs.

Why T-Nuts Matter in Modular Builds?

T-nuts are the backbone of any aluminium profile system. Here’s why they matter:

No drilling required – They use the built-in profile grooves

Flexible design – Easy to add or move parts later

Fast assembly – Reduces time and tool usage

Clean look – Mounting is hidden inside the slots

Reliable hold – When tightened, they form a strong connection

In other words, if aluminium profiles are the structure, T-nuts are the screws that make the structure flexible, adjustable, and modular.

How to Install a T-Nut (Step-by-Step)

Let’s walk through a basic installation:

Choose the right size – Match the T-nut to your profile (e.g., 2020 or 2040) and bolt thread (e.g., M5)

Insert the nut into the T-slot — either by sliding or dropping it in

Align your bracket or component over the threaded hole

Insert and tighten the bolt using a hex key or Allen wrench

Done — you now have a secure mount!

For larger builds, it’s smart to pre-load several T-nuts into the slots where you plan to mount components later.

Pro Tips

Use spring-loaded T-nuts if you’re constantly adjusting parts

Pre-load T-nuts before full assembly to save time later

Label bolt sizes for consistent assembly across projects

Buy extras — they’re small but easy to lose or miscount

Compatible with Most Profiles

T-nuts are available for various metric and imperial profile systems. For example:

2020, 3030, 2040 metric profiles (common in Canada and the EU)

10 series, 15 series imperial profiles (popular in the U.S.)

At Zivon, we focus on metric sizes commonly used in hobby, industrial, and maker environments across Canada.

Looking for T-Nuts in Canada?

If you’re sourcing aluminium extrusion accessories locally, you’ll often run into limited stock or long international shipping delays.

At Zivon, we aim to solve that by offering:

A growing selection of T-nuts and accessories

Compatibility with popular profile sizes (like 2020, 2040, etc.)

Fast, reliable shipping across Canada

Helpful customer support if you’re unsure what to choose

What’s Next?

This post is part of our beginner-friendly series on aluminium extrusion systems. If you’re just starting out or planning a new build, check out these related guides:

[Aluminium Extrusion Profiles: A Practical Guide for Builders and DIY Projects]

We’re building a full resource hub to help Canadian makers, builders, and engineers get the most out of aluminium profiles.